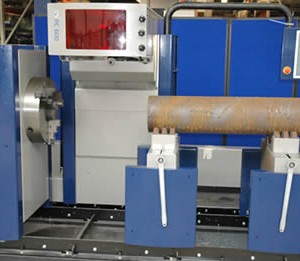

Product Description

Specification:

- The CNC ProCutter 600 handles pipe up to 24″ in diameter and 40 ft. in length to address the typical broad range of applications that confronts a structural steel fabricator in today’s market. The unit can be furnished with oxy-fuel or plasma depending upon the application. This system can also be fully interfaced with such CAD packages as Tekla.

| BASIC DAT- PROCUTTER PC600 | |

| Suitable for Pipe Range (Outside Diameter) | 50-610mm |

| Machine Length for 6,000mm Pipe Lengths | 9,143mm |

| Machine Length for 12,000mm Pipe Lengths | 15,137mm |

| Machine Width/Depth | 2,418mm |

| Machine Height | 1,945mm |

| Machine Weight for 6,000mm Pipe Lengths | 2,650kg |

| Machine weight for 12,000mm Pipe Lengths | 3,485kg |

| Maximum Pipe Weight | 3,000kg |

| Maximum Pipe 6,000mm | Incl |

| Maximum Pipe 12,000mm | Option |

| Minimum Pipe Length (including 10mm Clamping Length) | 375mm |

| Admissible Ambient Temperature | -10 to +45° Celsius |

| Integrated Foundation Frame | Incl |

| CE Compliant | Incl |

| PIPE ROTATION/MAIN DRIVE | |

| Adjustable Height Main Drive incl. | Incl |

| Height Movement | Hydro pneumatic |

| Opening and Closing | Manual |

| PIPE SUPPORT | |

| 2 no. Pipe Trolly Max. Load 1,500kg each (fixed height) | Incl |

| Prisma Rollerball Gutter Ø50 to Ø400 | Option |

| CUTTING TROLLEY | |

| Pantograph Cutting Head | Incl |

| Vertical out of Roundness Compensation Mechanism | Incl |

| Maximal Longitudinal Speed | 20,000mm/min |

| Cutting Stroke/ Torch Travel of 6,900mm | Incl |

| Cutting Stroke/ Torch Travel of 12,900mm | Option |

| Pneumatic Height axe | Incl |

| CONTROLLER | |

| Industrial PC with Windows XP embedded (solid state with flash drive) | Incl |

| Sigmatek CNC System | Incl |

| Human Machine Interface with 17inch TFT Colour Screen | Incl |

| USB | Incl |

| Lan Package (network connection) excl cabling | Incl |

| SOFTWARE | |

| Manual Machine Programming (MDI) | Incl |

| Manual Offfice Programming (OPPL) | option |

| CAD/CAM Connection | option |

| Auto Nesting Program (AN) | option |

| MACHINE ACCURACY | |

| Main Drive Rotation | +0.25° |

| Cutting Trolley Longitudinal Movement | +0.5mm |

| Torch Lifting | +0.5° |

| CUTTING ACCURACY | |

| Based of Circular Pipes with Constant Wall Thickness | |

| In compliance with DIN2310, Tolerance class C and Quality Part 4, Quality 1 | Incl |

| Cutting Length | +15mm |

| Bevel | +2° |

| CUTTING PROCESS | |

| Oxyfuel | |

| Wall Thickness Range at 45° Cutting Angle from 3-50mm | Incl |

| Electric Gas Valves and Ignition | Incl |

| Plasma | |

| Kjelberg FineFocus450 (43 kVA) Air Plasma Wall Thickness Range at 45° Cutting Angle | |

| 31mm Max. Quality Cut 24mm | Option |

| O2 Cutting Ar/H2 Cutting Ar/H2/N2 Cutting | Option |

| FLUME EXHAUSTION | |

| Fume Exhaustion Point Spark Collector at Main Drive (excl Ventilator) | Option |

| CONSUMPTION | |

| Tot. Consumption 380-440V+ 10%-10% 3 Phase +earthground 50Hz (Oxyfuel)kVA 12 | 12kVA |

| Tot. Consumption 380-440V+ 6%-10% 3phase +earthground 50Hz (Oxyfuel)kVA 46 | 46kVA |

| Machine, Compressed air 6 bar, not Greased, non Condensed (dow point 4° | 40Nl/min |

| Oxyfuel cutting, Acethylen for t=50mm and 45° Cutting Angle at 1.5 bar | 50Nl/min |

| Oxyfuel cutting, Oxygen for t=50mm and 45° Cutting Angle at 10 Bar Purity 98% | 270Nl/min |

| Plasma Cutting Compressed air, 6 bar, not Greased, non Condensed (dow point 4°) | 26Nl/min |

| Plasma Cutting O2, 6 bar, 99% Purity | 25Nl/min |

Reviews

There are no reviews yet.